Without a ceramic membrane gases must be cooled before separation.

Ceramic membrane for gas separation.

Unfortunately even though ceramic membranes can improve the productivity for many reactions and separations in the chemicals and refining industries they are costly.

History manufacturers of ceramic.

The membrane used in the process is a generally non porous layer so there will not be a severe leakage of gas through the membrane.

Ceramic membranes can be used for the separation of single gases from gas mixtures or in membrane reactors.

An example of an amorphous membrane is the silica membrane.

Innovative ceramic membrane reduces energy and cost of industrial gas separation ceramic membranes offer great potential for industrial gas separation.

An example of a highly porous membrane is the type made of silicon carbide.

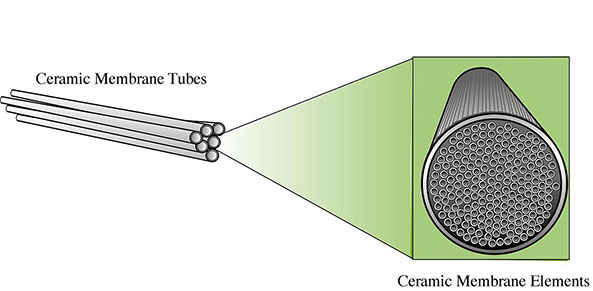

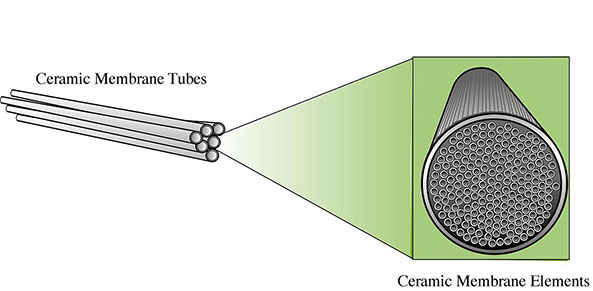

Ceramic membranes include pores with a defined average size ranging from macrometers to nanometers and they can be used for liquid filtration gas separation and pervaporation.

Gas separation across a membrane is a pressure driven process where the driving force is the difference in pressure between inlet of raw material and outlet of product.

The achievable flow rate and the durability of the membrane depend strongly on the ceramic powder that was used for the production of the active layers of the membrane.

They can be made from both crystalline as well as amorphous solids.

2 ceramic membranes for gas separation in the past decade intense research efforts have been made in the development and improvement of inorganic membranes for use in separations that are difficult to achieve by conventional poly mer membranes i e high temperature separa.

Starting by documenting established procedures of ceramic membrane preparation and characterization this title then focuses on gas separation.

Herein we developed a zif 62 mof glass membrane and exploited its intrinsic gas separation properties.

Porous ceramic membranes are chiefly used for gas separation and micro or nanofiltration.

The mof glass membrane was fabricated by melt quenching treatment of an in situ solvothermally synthesized polycrystalline zif 62 mof membrane on a porous ceramic alumina support.

Hydrogen separating membranes 1 200 000 t a will be retrieved.

Ceramic membranes for reaction and separation is the first single authored guide to the developing area of ceramic membranes.

Common for all ceramic gas separation membranes is the operation under harsh conditions of high temperature and large gradients of pressure.