Green diamond foundry sand is available in ferrous and non ferrous foundry grade sands and is the ideal silica free replacement for olivine and silica sands for molding and coremaking.

Ceramic foundry sand silica replacement.

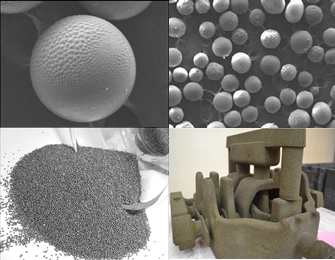

Supersand is a spherically shaped bauxite sand manufactured by melting bauxite in an electric arc furnace followed by a proprietary spraying process.

It is an artificial foundry sand that is regarded as the right substitute for chromite sand ziron sand and fused silica sand.

This ceramic sand is made from a bauxite based material which produces hard particles that last longer than other ceramic medias on the market.

Due to ceramic sand s unique physical and chemical properties it can be used in a wide variety of foundry processes.

Indian foundries produce approximately 1 71 million tons of waste foundry sand each year metal.

Ceramic ball bauxite china foundry sand perfect replacement for silica sand qingdao duoyuan new materials co ltd.

It is produced from ferrous and nonferrous metal casting industries where sand has been used for centuries as a moulding material because of its thermal conductivity.

It is well regarded as a revolutionary new foundry sand.

Sphereox ceramic foundry sand versus silica sand has a lower thermal expansion resulting in higher precision and accuracy of castings while also leading to lower scrap cost and cost to correct inaccuracies.

It reduces the occurrence of casting defects such as veining penetration and burn on resulting in lower cleaning cost.

Supersand is a ceramic sand.

As the largest and the best ceramic foundry sand manufacture in the world the main product is kailin ceramic foundry sand and it also manufactures a variety of auxiliary foundry products and with the great reputation established over.

Supersand beaded foundry sand provides a unique combination of spherical shape grain chemistry and physical properties that result in.

Ceramsite sand supersand is also called ceramiste ceramic foundry sand and nice foundry sand.

Foundry sand is high quality silica sand with uniform physical characteristics.

Unlike silica sand carbo ceramic casting media produces no respirable silica dust so it easily complies with osha 1926 1153 silica dust permissible exposure limits pel.

With smooth surface and perfect shape ceramic sand has smallest superficial area making the volume added to adhesive and curing agent much less average 40 50 less.

The company developed kailin ceramic foundry sand in 1999 and gained over 20 patents in foundry industry area.

Replacing silica sand with carbo ceramic casting media is the most cost effective way for a foundry to meet osha requirements for silica dust exposure.

Refractory engineers offers a unique foundry sand by the name of supersand.