Classification scheme for ceramic forming methods 2.

Ceramic forming techniques ppt.

Forming pressing ceramic particulate raw materials can be pressed in the dry plastic or wet condition into a die to form shaped products.

Methods for forming ceramic powders into complex shapes are desirable in many areas of technology.

Adapted from manufacturing engineering and technology s.

For example such methods are required for producing advanced high temperature structural parts such as heat engine components.

Introduction ceramic powders ceramic particle suspensions casting pressing extrusion injection molding extraction of organic shaping additives deposit.

11 7 2 5 green machining after forming the ceramic shape often is machined to eliminate rough surfaces and seams or to modify the shape.

Foremost among these techniques are pressing and extrusion.

After the raw materials are mixed and blended into a stiff mud or plastic mix a variety of forming techniques are employed to produce useful shapes depending upon the ceramic involved and the type of product desired.

Aliah university what is ceramics ceramics are compound of metallic and non metallic element.

3 types of pressing.

Ceramic forming techniques are ways of forming ceramics which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts.

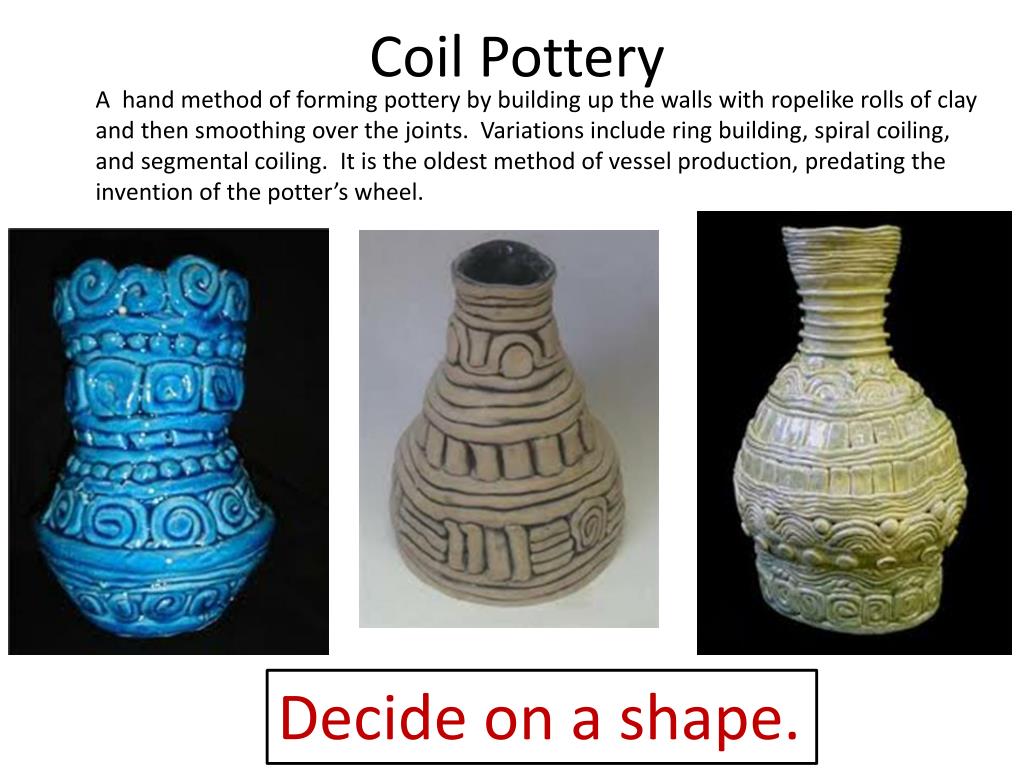

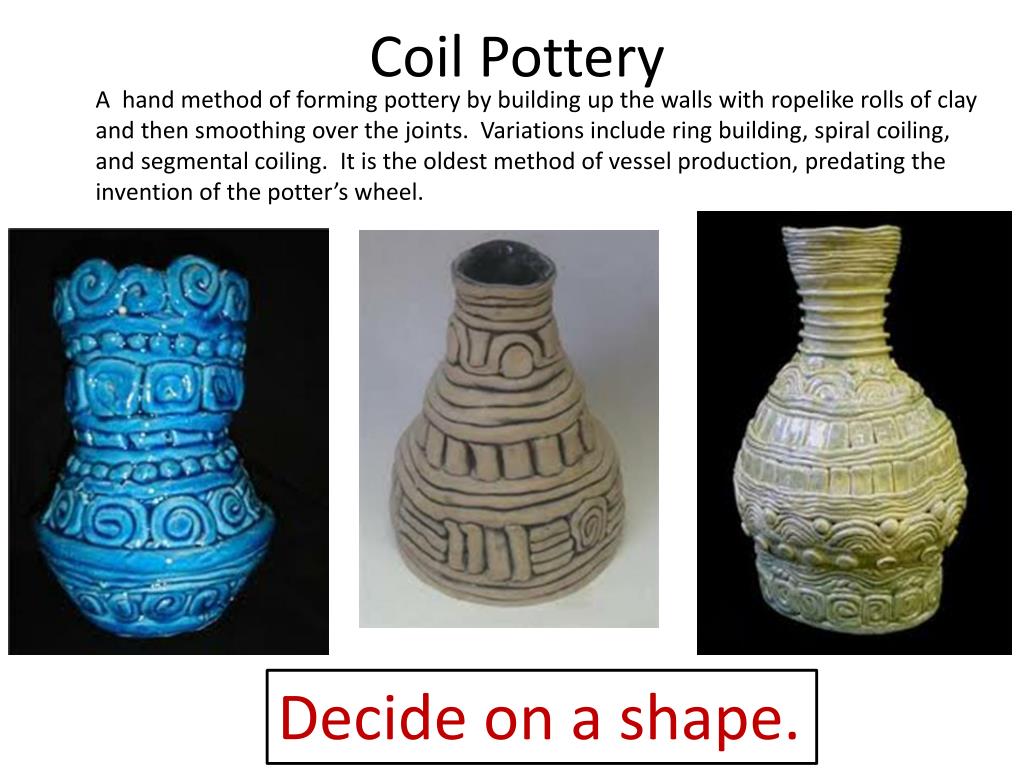

Pottery techniques include the potter s wheel slipcasting and many others.

Basic steps of shaping.

The methods used to machine green ceramics include surface grinding to smooth.

Ceramic sheets or tape which can be cut and stacked to form multilayer ceramics for capacitors and dielectric insulator substrates.

The term ceramics refers to both the material and to the ceramic product itself the greek word keramos means potters clay from there the word ceramic came.

Plastic forming also called soft wet forming can be carried out by various methods such as extrusion injection molding or molding and jiggering.

Ceramic shaping process presented by asifur rahman dept.

Forming the powder is consolidated into a compact by shaping in a mould die with the application of pressure cold compaction and or heat hot compaction water and or plasticisers are added to allow the paste to be fo rmed into the desired shape common forming methods include.

For some other ceramic products the raw materials are ground dry along with binders and other additives.

This can be used to make everyday tableware from teapots to engineering ceramics such as computer parts.

Ceramic forming techniques are ways of forming ceramic shapes.

Mits me 312 manufacturing technology 13.

Https bit ly 2x3blzg ceramic fiber is a fibrous refractory material a light weight high temperature good thermal stability low thermal conductivity specific heat of small and resistance to mechanical shock etc luyang energy saving materials morgan thermal ceramics and unifrax captured the top three.

Kalpakjian vikrant sharma fet.

Global ceramic fiber market insights forecast to 2026 free research report pdf.

Summary this chapter contains sections titled.