Additive manufacturing am of ceramics is coming to an aera where the first industrial applications are becoming economically profitable.

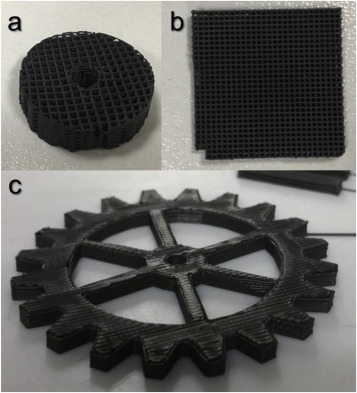

Ceramic coated gear additive amnufacturing.

Cleveland airport marriott cleveland ohio held in conjunction with ceramics expo 2019 instructors.

Currently the density of the ceramic parts made by binder jetting is low and their mechanical properties are inferior.

Ceramics additive manufacturing has been.

Binder jetting additive manufacturing has demonstrated its considerable capability in manufacturing ceramic parts with a complex shape and or a customized design.

In the present work a multi material process allowing for realization of a ceramic coating on a steel substrate and a novel sandwich system are introduced.

When it comes to additive manufacturing the wide range of ceramic applications and material types is further expanded by the even wider range of different ceramics additive manufacturing processes that have been and are continuously researched validated and implemented in ceramic manufacturing.

However additional functionality of the structures built e g local insulation is desirable for more sophisticated applications.

This review paper provides a survey of am methods reported in literature to shape ceramic components.

Allan vice president lithoz america llc.

It demonstrates that am has produced ceramic parts that have no cracks or large pores and have.

In a first step a basic overview of different classes of ceramics their characteristics and conventional manufacturing routes are discussed.

Learn how ceramic additive manufacturing can be an alternative to conventional manufacturing methods april 29 2019 8 30 a m 4 30 p m.

In this study laser engineered net shaping lens tm was employed towards additive manufacturing 3d printing of ti si n coatings with three different ti si ratios on commercially pure titanium cp ti substrate microstructural analysis phase analysis using x ray diffraction wear resistance and hardness measurements were done on lens processed 3d printed coatings.

Holly shulman professor alfred university.

The main reason is the low sinterability of the powder feedstock.

The chapter laser additive manufacturing of ceramic components.